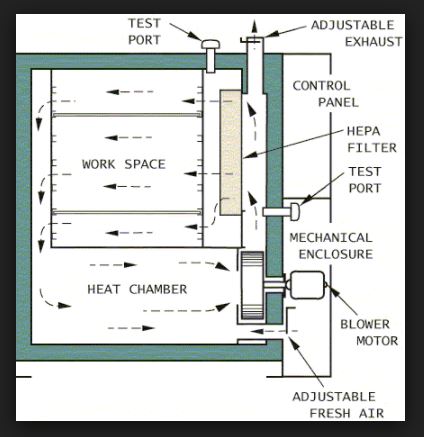

Airflow Controlled Environments are ideally suited to a wide range of industrial uses and are available in many different sizes types. Most industrial ovens designed for curing are rated at a maximum of about 500 degrees Fahrenheit 260 degrees Celsius.

Pdf Design Fabrication And Performance Evaluation Of Domestic Gas Oven

Close Log In.

. THEORY AND CONSIDERATIONS FOR DESIGN INDUSTRIAL OVEN AND BATCH OVEN PROCESS APPLICATIONS Industrial ovens are used in a wide range of applications including aging annealing baking composite curing curing drying finishing heat treating melting powder coating ovens. U Whether the heat-up rate needs to be controlled or if the product can be. HAUCK MEMBER IEEE Abstract-The heating mechanism in a microwave oven results from the interaction of a high-frequency electromagnetic field and thefoodwithin it.

Download as PDF TXT or read online from Scribd. Acces PDF Industrial And Process Furnaces Principles Design And Operation PDF Heat Transfer Calculation in Furnaces Replace your old natural gas furnace with an eligible ENERGY STAR model and you could qualify for a rebate of up to 1000Plus if you install an eligible connected thermostat you could qualify for an additional 150 rebate. Industrial oven insulation ensures that the oven heats to the required temperature.

The size can range from small bench top units to large industrial installations with thousands of cubic feet. The design of each Sahara Industrial. The senior project discusses the design construction and analysis of a conveyor system for drying seasoned snack almonds.

FUNDAMENTAL PRINCIPLES OF DRYING _____ 4 Drying with heated air implies humidification and cooling of the air in a well-insulated adiabatic dryer. Thus hygrothermal properties of humid air are required for the design calculations of such dryers. Oven Cleaning Oven maintenance is a critical issue in the design.

Full PDF Package Download Full PDF Package. High quality insulation of the proper density and compressed into the ovens panels helps avoid heat leakage and keeps the exterior cool. Inmostovens the field is generated byamagne-tron which converts dc energy to high-frequency energy at approx-imately 2450 MHz.

- A study to design fabricate and performance evaluation of the domestic gas oven was carried. Established applications to date are summarised. The usage of the oven and its size can be determined only when you.

Temperatures in the oven can exceed 400 F. Inside Width in inches x Inside Length in inches x Inside Height floor to return duct bottom in inches 1728. Observation of these rules will help a powder coater acquire and maintain a dependable oven.

The current oven drying method used at Nunes Farms is inefficient and in need of a replacement solution. We take a modern approach to the design and manufacturing of industrial ovens and furnaces. It will be necessary.

Guidelines for Choosing the Appropriate Industrial Oven. Precision Quincy sells industrial ovens with a perfect fit We are proud of our 70-year legacy and the Precision Quincy name that we attach to every industrial oven design that leaves our facility in South Beloit Illinois. Industrial Oven Selection Guide 06-17 WWWDESPATCHCOM.

Though industrial ovens operate at close to 1250 F their exterior must be cool to the touch. 122 House Keeping The inside of the oven top of the oven and sides of the oven. Bench-mounted or small cabinet-style ovens are.

Oven Type There are two types of conveyor ovens. Industrial use in clean air applications Backward Inclined BI Fans Efficiency slightly less than airfoil 10-12 single thickness blades inclined away from the direction of rotation Relatively deep blades provide for efficient expansion within blade passages Primarily used in general HVAC systems Industrial applications. The oven is designed to replace 20 of the air with fresh air in order to maintain low levels of CO but caution should be used in case of an unsafe CO level inside of oven.

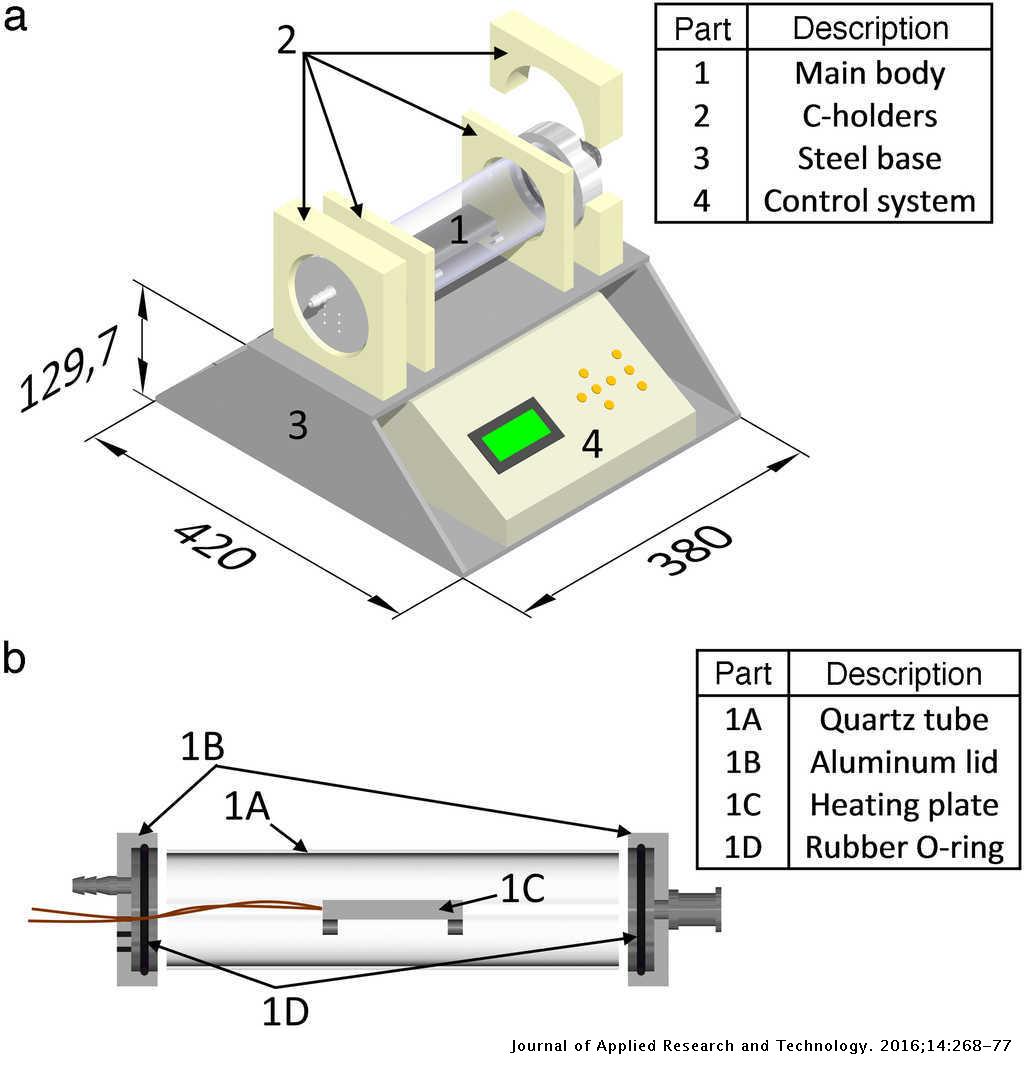

The pilot plant oven is a special batch oven designed to emulate continuous convection tunnel oven baking. Save Save Technical Reports _ Principles of Oven Designpdf For Later. Principles Design and Operation.

Continuous conveyor ovens and indexing conveyor ovens. INDUSTRIAL OVENS BATCH OVENS AND COMPOSITE OVENS. Spotting the application requirements is the first and the most vital step.

Continuous conveyor ovens move product through them at a steady rate and are best when you have large volumes of similar parts that require thermal processing. Ovens that are used in various industrial heating and drying processes make it tough for us to choose them. The principles of microwave heating as applied to industrial processing are outlined and the basic design of applicators for material processing is described.

The report will follow the project through the initial design construction and testing of the conveyor. Indexing conveyor ovens use a stop-and-go sequence to move product through them. Pattern ers blowers and exhaust All heat.

Knowing the volume of air your oven holds is necessary in order to determine the air flow rate. A short summary of this paper. Transporting product in and out of the oven.

Principles Design and Operation. This is sufficient for most paint and powder applications although there are a few coatings Teflon for example that require a higher temperature. Airflow are the leading UK manufacturer of Industrial Ovens.

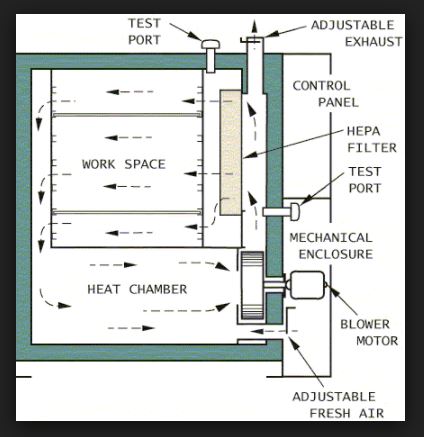

The design construction and validation of the oven has been part of. Ask your paintpowder supplier what cure time and temperature are required. You will find them in several options.

Oven is centered around temperature uniformity. 0 found this document useful 0 votes 765 views 7 pages. Industrial and Process Furnaces.

Design Considerations for Microwave OvenCavities HAROLD S. Industrial applications range from food tempering to rubber vulcanisation and from vacuum drying to sintering of ceramics. Emperature uniformity is critical to T the proper operation of an oven ocess and load placement Heating pr will dictate the required airflow.

Log in with Facebook Log in with Google. The oven design will need to have sufficient heating capacity to bring the product to the desired temperature within the specified time. 37 Full PDFs related to this paper.

These ovens represent the largest category of ovens used to manufacture products Batch-type ovens can be classified as cabinet-style or truck-loaded type. The oven was designed and was fabricated with an outer dimension of 450 mm length. Flag for inappropriate content.

Airflow Industrial Ovens Overview. Table 1 summarizes the essential thermodynamic and transport properties of the air-water system. The specification design manufacturing installation and commissioning process is offered as a complete package.

5 General Oven Design Operation There are some general rules that govern standard good practice in the design and operation of process ovens.

Pdf Ppt Hot Air Oven Working Principle Sterilization Diagram Sop Uses Temperature Pharmawiki In

Convection Ovens An Overview Sciencedirect Topics

A Dedicated Electric Oven For Characterization Of Thermoresistive Polymer Nanocomposites Journal Of Applied Research And Technology Jart

Industrial Oven Improvement For Energy Reduction And Enhanced Process Performance Springerlink

Pdf Industrial And Process Furnaces Principles Design And Operation Pedro Juan Academia Edu

Pdf Dynamic Heat And Mass Transfer Model Of An Electric Oven For Energy Analysis

Technical Reports Principles Of Oven Design Pdf Pdf Heat Transfer Heat Exchanger

0 comments

Post a Comment